Page 1 of 1

Edge waste/layout question

Posted: Sat Mar 31, 2018 5:21 pm

by Zombo

So, I've accidently put the cart before the horse and found some amazing slabs before finding a fabricator. I want to buy them before they're snatched up, but have one measurement that I'd like some input on. If the slabs are in good condition, how much edge waste is typical? The slab is 69" high and one piece ("D") needs to be 65" in that direction. Is two inches per side a good enough margin?

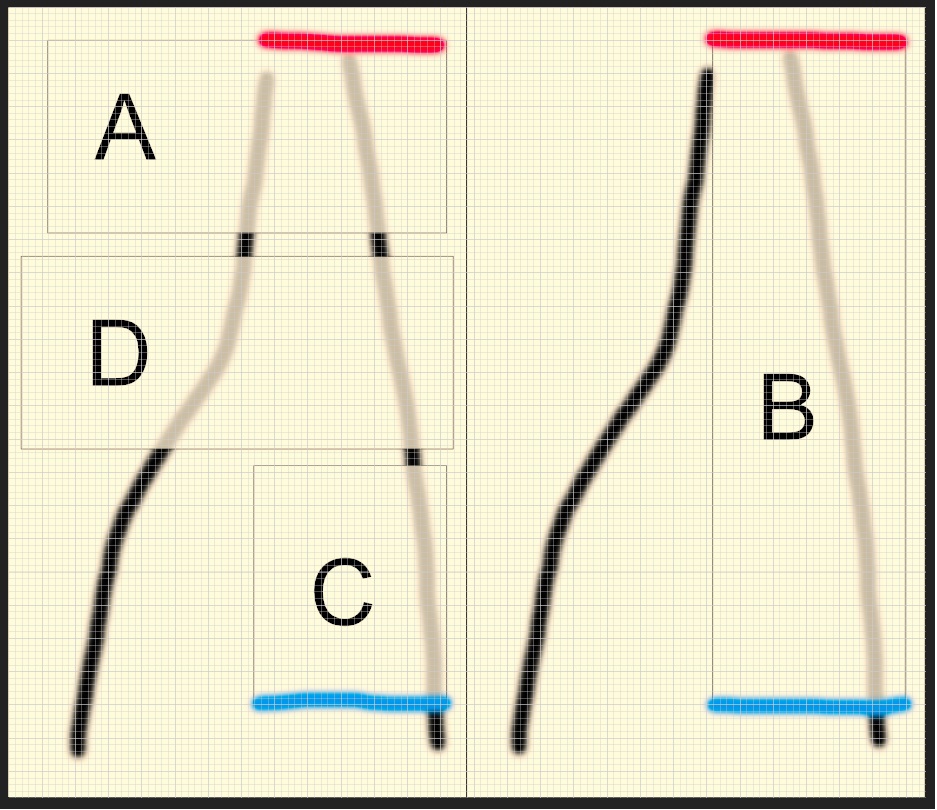

I've hacked together a quick and dirty drawing below. The weird black waves are there to simulate the movement. A, B, and C get book-matched according to the funky colors. D is the questionable piece. I'm hoping to get a bathroom countertop out of the remainder of the second ("B") slab. Any other issues that I should be concerned about? Better way to do this?

- slab.jpg (270.73KiB)Viewed 318 times

Appreciate any and all comments, suggestions, and constructive criticism. Thanks!

Re: Edge waste/layout question

Posted: Sat Mar 31, 2018 6:45 pm

by Ken Lago

Horse before the cart is correct. Find a good fabricator first, it's not as simple as you think getting a good vein and color match.

Those are not bookmatched slabs so book match is not happening.

Re: Edge waste/layout question

Posted: Sat Mar 31, 2018 7:08 pm

by Andy Ross

B and C don't line up...they're opposite each other. 2" margin is ok on square slabs with no damage on the edges. They could easy get damaged during transport to the fabricator or even moving them around the shop.

Re: Edge waste/layout question

Posted: Sat Mar 31, 2018 7:27 pm

by Zombo

Andy Ross wrote: ↑Sat Mar 31, 2018 7:08 pm

B and C don't line up...they're opposite each other. 2" margin is ok on square slabs with no damage on the edges. They could easy get damaged during transport to the fabricator or even moving them around the shop.

[

Appreciate the feedback. What would be the least amount of margin on the edges you'd work with?

Re: Edge waste/layout question

Posted: Sun Apr 01, 2018 6:56 am

by Andy Ross

I measure ours when we have it and I can inspect it. I would do the layout. If the yeild was tight, I would hold an additional slab at the supplier until the job was cut or I would add the extra slab into the estimate and order it. Depends on how I felt about the customer honestly.

Tag the slabs and let you fabricator do the rest.

Re: Edge waste/layout question

Posted: Sun Apr 01, 2018 7:01 am

by Ken Lago

The only way you can answer your questions is by making templates and then transfer them to the slabs. Then you have to look for fissues and scratches that could have happened during transportation to the fabricators shop. Also remember if you buy the slabs you will be 100% responsible for any breakage that could happen during the time its in the fabricators hands. So if the fabricator calls you up and say one of your slabs broke and he will need another slab, YOU would have to purchase another slab.

Re: Edge waste/layout question

Posted: Tue Apr 03, 2018 12:23 pm

by Omni Cubed Larry

Is this 3cm material. What edge detail? If you are laminating or mitering, you won't have enough material. Is backsplash needed for the job?

Those two slabs might be beautiful, but there are "plenty of fish in the sea". Find a good fabricator and work with them... you will increase your chances of success exponentially. Good fabricator first.