Sealer testing

Posted: Thu May 19, 2011 1:58 pm

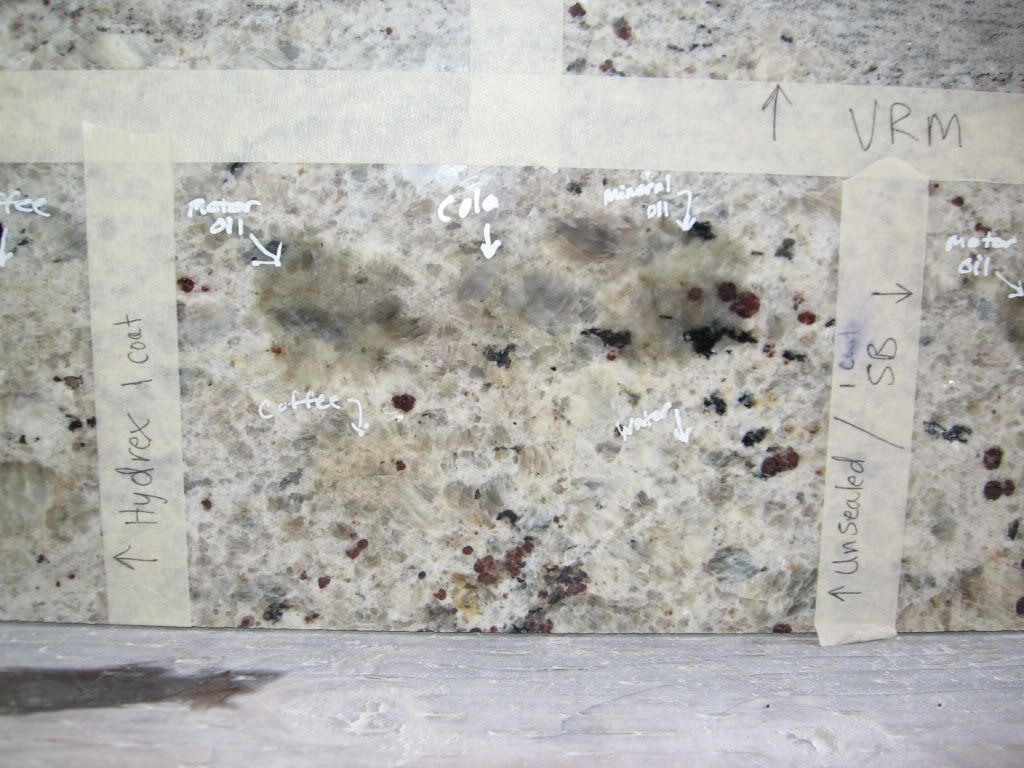

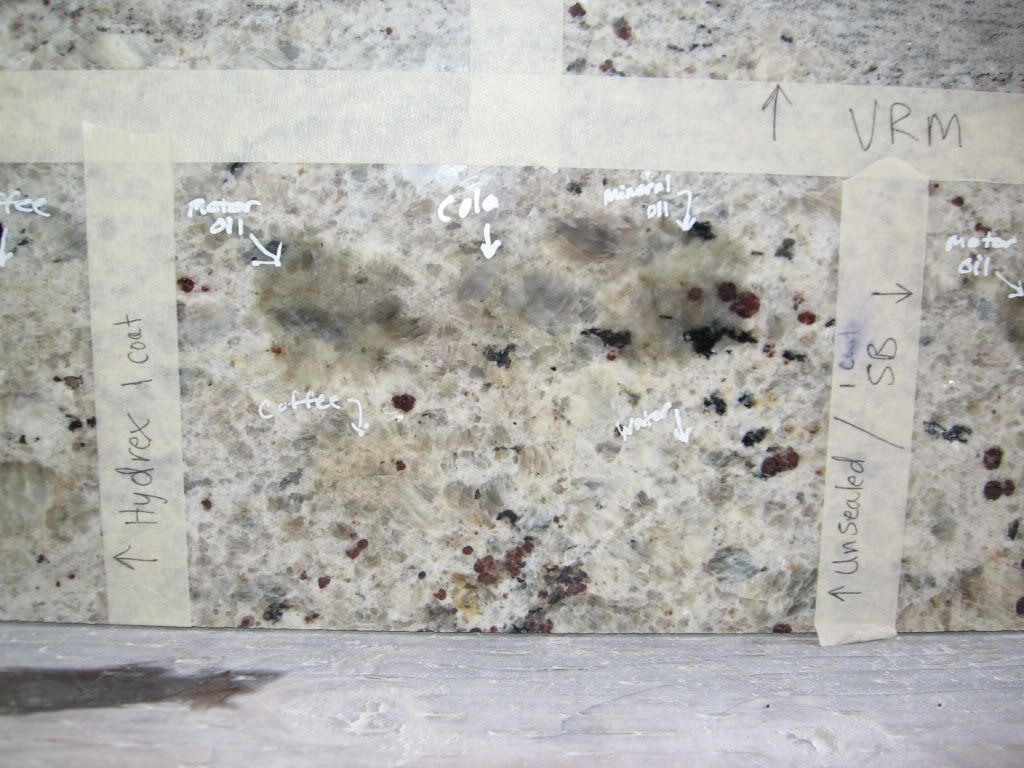

All testing was done on Kashmir White polished granite.

The sealers tested were Prosoco SLX-100 (1 coat and 2 coats), STT VRM (1 coat and 2 coats), Tenax Hydrex (1 coat), and STT SB (1 coat). I also tested an unsealed area.

Each of the sealers were applied as a light coat and kept wet on the surface for 1 minute then left on the stone for approximately 3 - 5 minutes before buffing off. The SLX-100 and the VRM only slightly darkened the stone and dried back the original color within a few minutes. The second coat of SLX-100 and VRM were applied about 10 minutes after the stone appeared dry. The SB darkened the stone more than the SLX-100 and VRM and took a couple hours to dry out. The Hydrex darkened the stone the most and took overnight to dry out. All sealers were easy to work with and buffed off easily.

The products used to test for staining were new motor oil, cola, mineral oil and coffee. I also tested with water by putting a piece of hard plastic over a puddle of water. The water test was done to represent a glass left on the counter with water under it, which seams to force the water into the stone creating rings and takes a while to dry out.

Each of the sealers mentioned above were subjected to the same test after allowing the sealers 24 hours to cure. Each of the products used to stain the stone were left on the stone for 24 hours.

The SLX-100 (1 coat) showed slight staining from all of the products, but the coffee was the most noticeable. When the plastic was lifted from the water puddle and the water was dried from the surface, there was a dark spot that took about 1 hour to dry out.

The VRM (1 coat) showed slight staining from the motor oil and coffee. There was no noticeable stain left from the cola and mineral oil. When the plastic was lifted from the water puddle and the water was dried from the surface, there was a dark spot that took about 2 hours to dry out.

The SLX-100 (2 coats) showed very faint staining from all of the products. When the plastic was lifted from the water puddle and the water was dried from the surface, there was a dark spot that took about 1 1/2 hours to dry out.

The VRM (2 coats) showed no staining from any of the products used except for the water test. When the plastic was lifted from the water puddle and the water was dried from the surface, there was a dark spot that took about 3 hours to dry out.

The Hydrex (1 coat) showed no staining from any of the products used. When the plastic was lifted from the water puddle the water under the plastic beaded up into a puddle and was easily wiped from the stone. There was no penetration of water and no dark spot left.

The SB (1 coat) showed significant staining from all of the products. When the plastic was lifted from the water puddle there was no water left as it had all penetrated into the stone. There was a slight dark spot from the water that dried out in less than 1 hour.

The unsealed stone stained badly from all of the products. When the plastic was lifted from the water puddle there was no water left and the stone was already dry underneath.

The winner of this test was the Tenax Hydrex. It outperformed all the others with only one coat. In addition it is the least expensive of the sealers tested. The Hydrex is about 1/3 the cost of the others which makes it a great value.

I have samples coming from Defusco of the Tenax Proseal and the Tenax Protex. Once I get those samples I will be performing another test.

The sealers tested were Prosoco SLX-100 (1 coat and 2 coats), STT VRM (1 coat and 2 coats), Tenax Hydrex (1 coat), and STT SB (1 coat). I also tested an unsealed area.

Each of the sealers were applied as a light coat and kept wet on the surface for 1 minute then left on the stone for approximately 3 - 5 minutes before buffing off. The SLX-100 and the VRM only slightly darkened the stone and dried back the original color within a few minutes. The second coat of SLX-100 and VRM were applied about 10 minutes after the stone appeared dry. The SB darkened the stone more than the SLX-100 and VRM and took a couple hours to dry out. The Hydrex darkened the stone the most and took overnight to dry out. All sealers were easy to work with and buffed off easily.

The products used to test for staining were new motor oil, cola, mineral oil and coffee. I also tested with water by putting a piece of hard plastic over a puddle of water. The water test was done to represent a glass left on the counter with water under it, which seams to force the water into the stone creating rings and takes a while to dry out.

Each of the sealers mentioned above were subjected to the same test after allowing the sealers 24 hours to cure. Each of the products used to stain the stone were left on the stone for 24 hours.

The SLX-100 (1 coat) showed slight staining from all of the products, but the coffee was the most noticeable. When the plastic was lifted from the water puddle and the water was dried from the surface, there was a dark spot that took about 1 hour to dry out.

The VRM (1 coat) showed slight staining from the motor oil and coffee. There was no noticeable stain left from the cola and mineral oil. When the plastic was lifted from the water puddle and the water was dried from the surface, there was a dark spot that took about 2 hours to dry out.

The SLX-100 (2 coats) showed very faint staining from all of the products. When the plastic was lifted from the water puddle and the water was dried from the surface, there was a dark spot that took about 1 1/2 hours to dry out.

The VRM (2 coats) showed no staining from any of the products used except for the water test. When the plastic was lifted from the water puddle and the water was dried from the surface, there was a dark spot that took about 3 hours to dry out.

The Hydrex (1 coat) showed no staining from any of the products used. When the plastic was lifted from the water puddle the water under the plastic beaded up into a puddle and was easily wiped from the stone. There was no penetration of water and no dark spot left.

The SB (1 coat) showed significant staining from all of the products. When the plastic was lifted from the water puddle there was no water left as it had all penetrated into the stone. There was a slight dark spot from the water that dried out in less than 1 hour.

The unsealed stone stained badly from all of the products. When the plastic was lifted from the water puddle there was no water left and the stone was already dry underneath.

The winner of this test was the Tenax Hydrex. It outperformed all the others with only one coat. In addition it is the least expensive of the sealers tested. The Hydrex is about 1/3 the cost of the others which makes it a great value.

I have samples coming from Defusco of the Tenax Proseal and the Tenax Protex. Once I get those samples I will be performing another test.